TrumpJet® from Wetend Technologies

-

Sappi, Skowhegan, ME, USA

Annual savings using TrumpJet®

- 290 millions gallons of water

- 36000 MWh

- over 10 000 tn of carbon dioxide

- 22% reduction in chemicals -

Label maker, China

- 20% reduction of chemicals used

- improved paper quality

-improved production runnability

- eliminated fresh water use

- investment paid back in 30 days -

Newsprint, Japan

- reduction of retention aid polymer consumption:50%

- pre-screen before:40-65 seconds

- post-screen: 2 seconds

- better formation and dewatering -

NewPage - Wisconsin Rapids

-saved 78 million gallons of water per year

- reduced energy consumption by 50,000 MMBTU per year

- reduced silica by 43% -

LWC Paper - Finland

- elimination of fresh water use

- reduction in cationic polymer consumption up to 35%

- consistency in paper quality improved -

World's largest WLC maker -China

- production: 4000 tn/day

- eliminated fresh water use

- improved paper quality

- reduced carbon dioxide

by 30 000 tons/year -

Liner and corrugated medium board Japan

- 10-15% reduction in consumption of Neutral polymer is achieved when APAM dosage level is the same as before -

Specialty paper - Finland

- better formation resulted in faster machine speed of 35-65 Ft./minute

- Reduced polymer consumption by 20-30% -

Fine Paper, Coated - China

- Fresh water savings: over 600 million gallons per year

- 30% reduction in use of chemicals

- Energy savings of 77 000 MWh

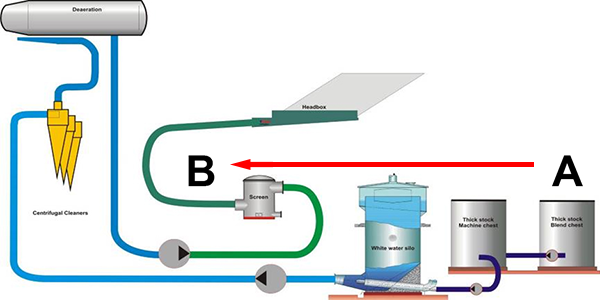

TrumpJet®Concept

Effective flash mixing of chemicals close to PM headbox brings considerable cost savings together with environmental benefits. TrumpJet patented techonology (US patent) makes it possible to use stock, white water or filtrate containing solids instead of fresh water. TrumpJet flash mixing reduces the amount of chemicals needed, saves energy and reduces carbon dioxide emissions.

TrumpJet®flash mixing versus conventional mixing

See the difference between flash mixing versus conventional mixing

in the video below.

1. Pioneer innovation

Pioneering innovations challenge conventional process chemistry and efficiently cut raw material costs with sustainable results.

TrumpJet with three nozzles provides instant mixing without delay.

Complete and effective mixing with the main flow allows dosing stations to be installed close to the headbox. It enhances the effects of chemicals. The response time is quick and there is no chemical losses.

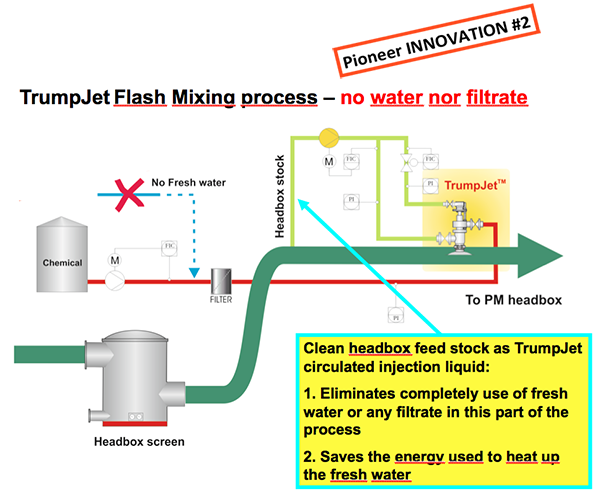

2. Pioneer innovation

Clean headbox feed stock completely eliminates use of fresh water or any filtrate- saves energy used to heat up fresh water/filtrate.

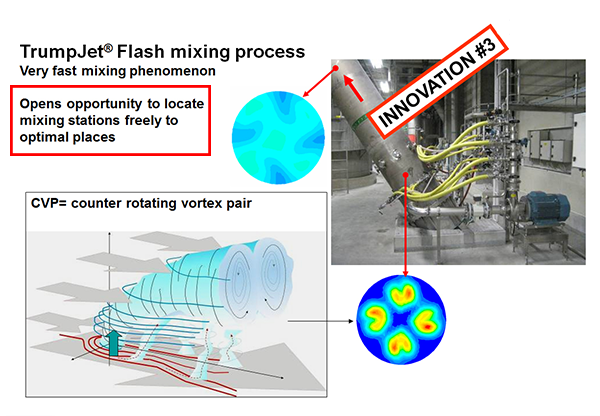

3. Pioneer innovation

ADVANTAGES OF FLASH MIXING ADDITIVES CLOSE TO HEADBOX WITH TRUMPJET®:

- Efficiency of chemicals will be increased due to thorough powerful flash mixing and very short delay time in process before dewatering and sheet formation.

- Recirculation of chemicals in the approach flow system will be

practically eliminated, which further increases efficiency of chemicals and improves

operational efficiency and product quality - Mixing several chemicals together simultaneously will give extra boost for efficiency

of chemicals, bringing additional savings

ALL THESE LEAD TO SAVINGS IN CONSUMPTION OF ADDITIVES/CHEMICALS, FRESH WATER, AND ENERGY. SAVINGS WITHOUT OPERATIONAL ISSUES (BUILDUPS, HOLES, BREAKS, PROFILE PROBLEMS ETC.) ARE ONLY ACHIEVED WITH COMPLETE FLASH MIXING TECHNOLOGY, WHICH GUARANTEES GOOD DISTRIBUTION AND DISPERSION OF ADDITIVES/CHEMICALS IN HEADBOX STOCK.

Complete flash mixing allows installing dosing stations close

to the headbox

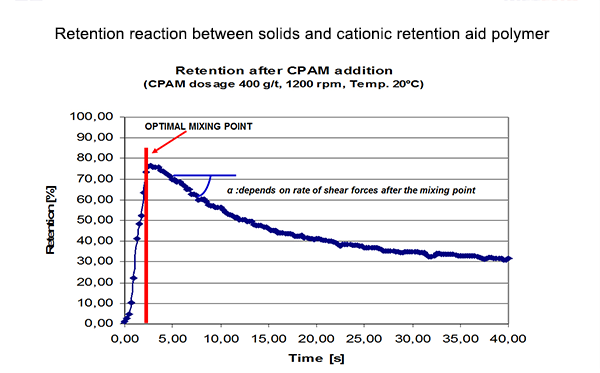

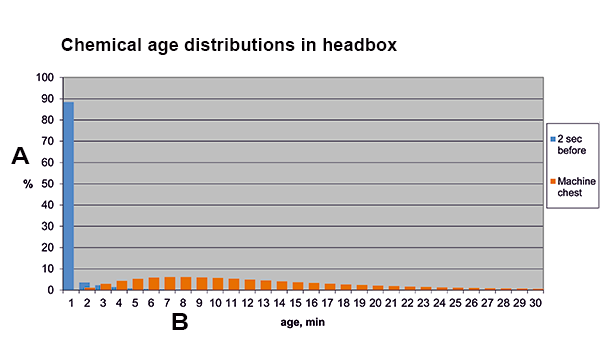

Time delay between mixing and dewatering

The efficiency of chemicals deteriorates the longer they stay in process

When dosed close to headbox efficiency of chemicals will be increased due to less time in process before dewatering. Average delay time in position B is only less than a minute compared to thick stock dosing of 7–10 minutes.

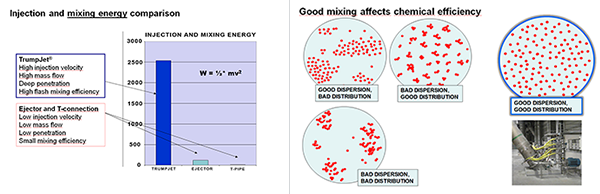

The advantages are possible only if mixing is done:

- by using high mixing energy

- by using headbox stock as injection media

High mixing energy is necessary for proper mixing of additives = Good dispersion and good distribution of chemicals and additives.

Unlimited use of headbox flow as injection media allows to increase mixing energy to a right level, which guarantees good dispersion and good distribution of additives in stock flow to headbox.

Using white water from other sources (white water, filtraits, etc.) create operational problems due to impurities and variations. Badly dispersed and distributed additives can further deteriorate PM efficiencies and product quality.

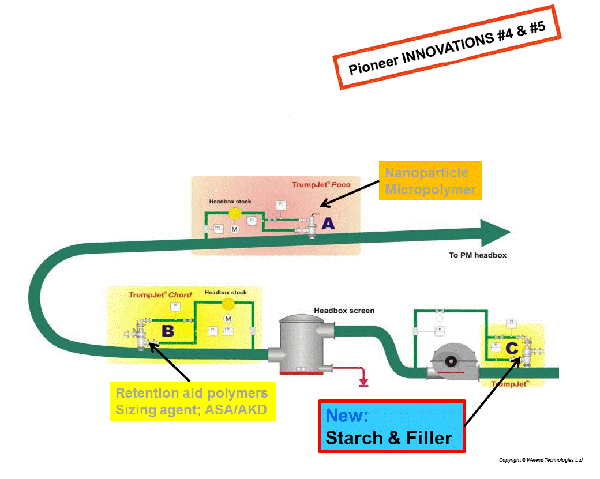

4. and 5. Pioneer innovations

ABC concept:mixing additives in pairs and groups close to the headbox - three mixing stations - six chemicals and additives

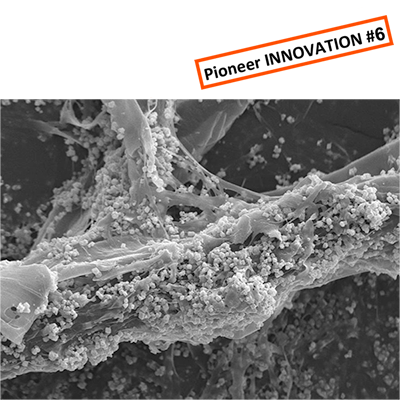

6. Pioneer innovation

In-Line PCC™ and other type reactor applications

New in-line production process of calcium carbonate integrated

into a papermaking process

TrumpJet®

- TrumpJet is a pioneering innovation challenging conventional process chemistry.

- It efficiently cuts raw material costs with sustainable results.

- Applications cover a wide range of wet additives with a novel manner.

Fresh water savings

- Fresh, clean water is a limited resource of nature.

- Today TrumpJet installations in operation save up to 15 billion gallons of water and reduce 2,5 million MWh water heating energy per year.

- TrumpJet technology offers cost savings that can be in millions of dollars for a mill.

Paper grades

- SC paper

- Newsprint paper

- Fine paper

- Coated fine paper

- LWC

- MFC

- Writing paper

- Printing paper

- Photographic paper

- Release paper

- Liquid packaging board

- Liner board

- Folding box board

- White chipboard

- Wall paper

- Corrugated Medium

- Coarse board

Chemicals used

- Retention aid polymer

- Retention aid bentonite

- Retention aid silica

- Retention aid microparticle

- ASA sizing agent

- AKD sizing agent

- GCC

- TiO2

- Paper Dye

- Starch

- Deinking Chemical CaOH2

- Sludge dewatering polymer

- Microflotation polymer

- Microflotation bentonite

- Biocide

- Size resin

- Dry strength agent

- Defoaming agent

- PAC

TrumpJet® Product Line

- TrumpJet

- - shear sensitive chemicals

- - polymer, filler, starch

- - ASA, AKD

- Forte

- - shear tolerant

- - bentonite, micro particel

- - sizing agent, ASA, AKD

- - de-inking Ca(OH)2

- - gas

- Poco

- - minor flows

- - silica

- - dye, PAC

- - filler

- - defoaming agent

- Chord

- - multi chemical use

- - polymer, starch

- - ASA, AKD

- - filler

- Trombone

- - thick stock

- - sludge polymer

- - self cleaning function

- Prowetend Consulting

Olavi Göös

President

Pulp and Paper Specialist - Wetend Technologies